When a beam is subjected to torsion, it experiences twisting forces that can lead to various mechanical responses and structural changes. Understanding the phenomena associated with beam torsion is vital for engineers and architects in designing safe and efficient structures.

What is Beam Torsion?

Beam torsion refers to the twisting of a structural beam due to applied torque.

Key points to note include:

- Torsion occurs in materials like steel, wood, and concrete, among others.

- It can be caused by various factors, including applied loads, supports, and the geometry of the beam.

- Understanding beam torsion is important for structural integrity and safety.

Different materials respond to torsion in unique ways, and various types of beams (e.g., rectangular, circular, I-beams) will exhibit different deformation patterns under the same loading conditions.

How Does Torsion Affect a Beam?

When a beam is subjected to torsion, it undergoes several transformations that affect its performance.

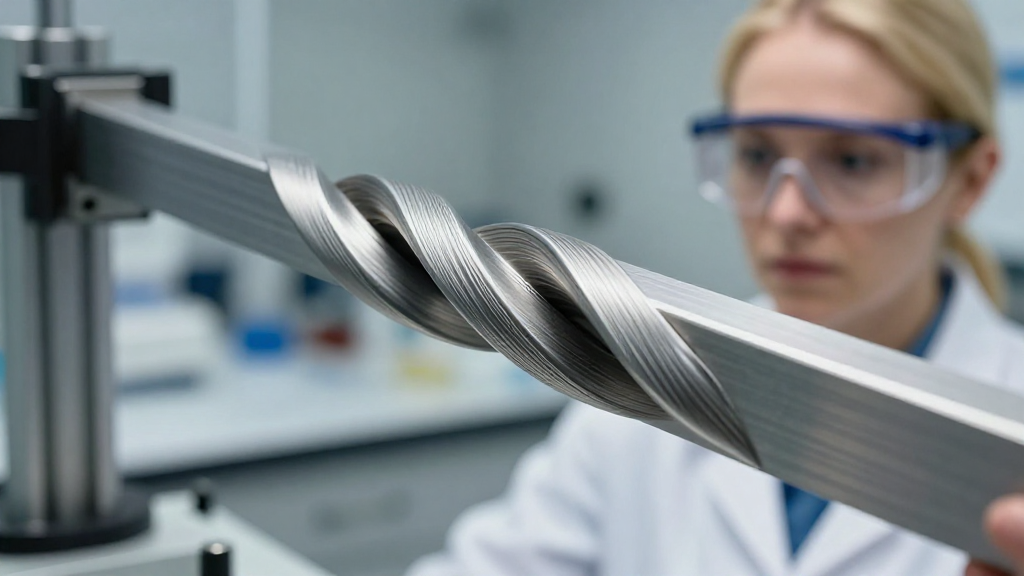

1. Twisting

Twisting is the most obvious effect of beam torsion. The beam will rotate along its longitudinal axis, causing one end to move relative to the other. This movement can lead to:

-

Shear stresses: Internal shear forces arise due to the differences in twisting along the beam’s length. These stresses can exceed the material’s yield strength and result in failure.

-

Angle of twist: This is a measure of how much the beam rotates under applied torque. The angle of twist is critical in design considerations, as excessive twisting can compromise structural safety.

2. Distortion of Cross-section

Torsion can cause the cross-sectional shape of a beam to distort.

-

Warpage: As the beam twists, the cross-section may experience uneven loading, leading to a warped shape. This warping can be particularly problematic in materials that are not ductile, as they may crack or break.

-

Non-uniform shear stress: The shear stress distribution across the beam’s cross-section becomes non-uniform due to the twisting action, leading to potential failure points within the structure.

3. Failure Modes

There are different failure modes linked to beam torsion that engineers must consider:

-

Elastic Failure: In ductile materials, elastic deformation occurs first, allowing the beam to temporarily twist without permanent damage. However, if the applied torque exceeds the material’s limit, it can lead to plastic deformation.

-

Plastic Failure: If the load continues to increase beyond the yield point, the beam may experience permanent deformation or even failure.

-

Brittle Failure: In brittle materials, minor torsional loads can lead to sudden fractures without visible warning, which can be catastrophic.

What Factors Influence Beam Torsion?

Several key factors contribute to how a beam responds to torsion:

1. Material Properties

Different materials have varying levels of strength, ductility, and toughness, all influencing how they handle torsion.

- Young’s Modulus: The stiffness of the material determines how much it will deflect under load.

- Yield Strength: Materials with higher yield strength can withstand greater torsional loads before deforming.

2. Beam Geometry

The shape and dimensions of the beam significantly affect its torsional resistance.

- Cross-sectional shape: I-beams, T-beams, and rectangular beams differ in how they resist torsional forces.

- Beam length: Longer beams may twist more than shorter beams under the same loading conditions.

3. Loading Conditions

Understanding how loads are applied along the beam is crucial.

- Concentrated loads vs. distributed loads: Concentrated loads usually create more localized torsion, while distributed loads affect the entire span more uniformly.

- Type of loading: Static loads will produce different effects compared to dynamic loads due to the inertia effects in the latter.

How is Beam Torsion Tested?

Structural engineers often conduct several tests to assess how beams handle torsional forces:

1. Torsion Tests

These are experiments specifically designed to measure a beam’s response to twisting loads.

- Measurement of shear modulus: This test helps determine the material’s ability to resist shear deformation due to torsion.

- Recording angle of twist: Engineers calculate the angle of twist to evaluate structural performance.

2. Finite Element Analysis (FEA)

Modern engineering employs computer simulations such as FEA to analyze beam torsion behaviors.

- Detailed modeling of beam characteristics allows for predicting potential failure points.

- Simulations can replicate various scenarios, including different materials, geometries, and loading conditions.

What Solutions are Available to Mitigate Beam Torsion?

Engineers have several strategies to minimize the effects of beam torsion:

1. Reinforcement

Adding reinforcements can increase a beam’s resistance to torsional failure.

- Stiffening plates: Applying additional metal plates on the sides of a beam can enhance its ability to handle torsion.

- Composite materials: These materials can increase the overall strength-to-weight ratio while resisting torsional forces.

2. Choosing Optimal Beam Shapes

Selecting the right beam geometry can significantly improve torsional resistance.

- I-beams are often used because their geometry provides greater resistance against torsion compared to solid rectangles.

- Use of tubular sections can also improve performance, as circular geometry typically offers a better torsional stiffness.

3. Proper Load Management

Correct positioning and sizing of loads can minimize torsional effects.

- Load distribution: Ensuring that loads are applied evenly across the beam can help reduce concentrated torsional stresses.

- Avoiding eccentric loading: Eccentric loads can exacerbate torsion; thus, positioning loads properly is crucial.

Conclusion

Understanding what happens when a beam is subjected to torsion is critical for the design, construction, and maintenance of any structure. By recognizing the effects of torsion, engineers can design more resilient structures that withstand unexpected loads and prevent catastrophic failures.

Incorporating suitable materials, optimal beam geometry, and effective reinforcement strategies can mitigate the risks associated with beam torsion. Continuous advancements in testing techniques and materials science will further enhance our ability to manage beam torsion, securing a safer future in structural engineering and architectural design.