Understanding the beam stress-strain curve is vital for civil and structural engineers, materials scientists, and mechanics.

This curve provides crucial insights into the performance and behavior of structural materials when subjected to loads.

What Does a Beam Stress-Strain Curve Represent?

The beam stress-strain curve represents the relationship between the stress (force per unit area) and strain (deformation) characteristics of a beam material.

-

Stress is measured in Pascals (Pa) or pounds per square inch (psi).

-

Strain is a dimensionless quantity that describes how much a material deforms compared to its original length.

As a beam bends or is subjected to tensile or compressive forces, its material will experience both stress and strain.

By analyzing the beam stress-strain curve, engineers can assess mechanical properties such as:

-

Elasticity: The ability of the material to return to its original shape after the load is removed.

-

Yield Strength: The maximum stress the material can withstand without permanent deformation.

-

Ultimate Strength: The maximum stress the material can withstand before failure.

Why Is the Beam Stress-Strain Curve Important?

The beam stress-strain curve plays a pivotal role in structural engineering for several reasons:

-

Material Selection: Engineers can choose suitable materials based on their structural performance characteristics.

-

Failure Prediction: The curve can help predict when and how a beam may fail during loading conditions.

-

Design Optimization: By illustrating how materials behave under stress, engineers can design beams that maximize strength and minimize material use.

-

Quality Control: It provides a benchmark to ensure materials meet specified performance standards.

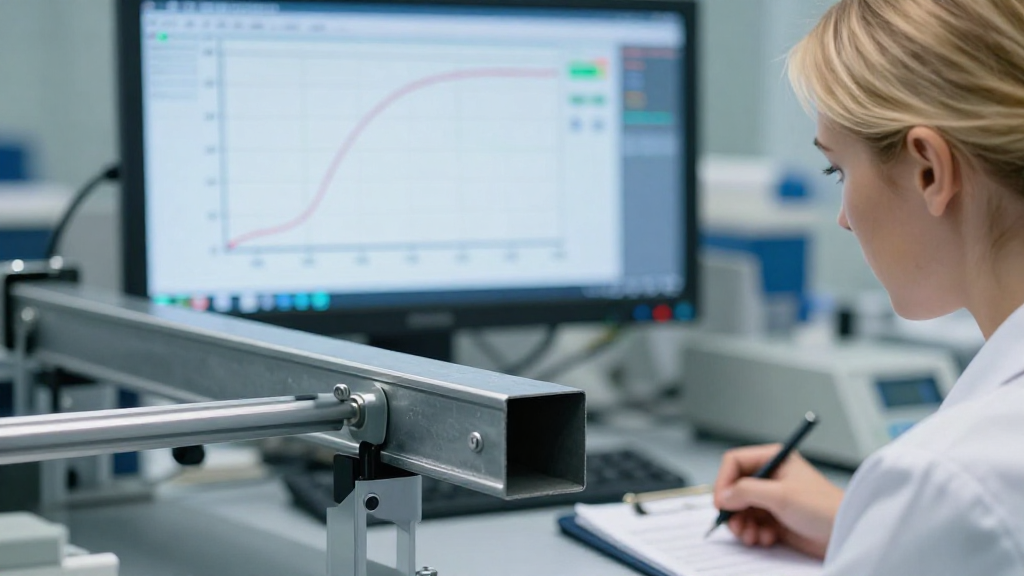

How Is a Beam Stress-Strain Curve Generated?

Generating a beam stress-strain curve involves a systematic testing process that typically follows these steps:

- Sample Preparation:

-

A beam specimen is prepared, usually with standardized dimensions.

-

Common materials include steel, concrete, wood, or composites.

- Testing Setup:

- The beam is placed in a testing machine that applies force until the beam fails.

- Data Collection:

- During the test, both the applied load (for calculating stress) and observed deformations (for calculating strain) are recorded.

- Plotting the Curve:

-

A graph is established with stress on the Y-axis and strain on the X-axis.

-

Points on this graph illustrate the material’s response at various loading stages.

What Are the Key Regions of a Beam Stress-Strain Curve?

The beam stress-strain curve typically includes several distinctive regions:

-

Elastic Region:

-

This is where the material behaves elastically, meaning it will return to its original shape after the load is removed.

-

It is linear, and the slope of this region is known as the modulus of elasticity.

-

Yield Point:

-

This is the point where the material starts to deform plastically.

-

Beyond this point, permanent deformation occurs, and the material does not return to its original shape when the load is removed.

-

Plastic Region:

-

Characterized by a nonlinear relationship, this region shows that the material can endure increased stress with continued strain.

-

Ultimate Strength Point:

-

The peak of the curve indicates the maximum stress the material can withstand.

-

Fracture Point:

-

Beyond the ultimate strength, the material fails, leading to complete fracture.

How Do Different Materials Affect the Beam Stress-Strain Curve?

The characteristics of a beam stress-strain curve can vary significantly depending on the material used. Here are a few examples:

-

Steel:

-

Exhibits a clear elastic region, followed by a distinct yield point.

-

Concrete:

-

Typically shows a more gradual rise in the elastic region, often without a distinct yield point.

-

Wood:

-

Displays a nonlinear curve due to its composite nature, including variations based on grain direction.

What Are the Applications of Beam Stress-Strain Curves in Engineering?

The application of the beam stress-strain curve is crucial in various fields, including:

-

Structural Engineering:

-

Used for designing beams in buildings, bridges, and other structures.

-

Mechanical Engineering:

-

Important in the design of machinery and tools subjected to various load conditions.

-

Materials Science:

-

Helps in studying new materials and composites, thus enhancing product performance.

-

Geotechnical Engineering:

-

Assists in understanding the behavior of soils and rock structures under load.

Conclusion: Why You Should Understand the Beam Stress-Strain Curve

In summary, the beam stress-strain curve is an essential tool for engineers and material scientists alike.

It provides significant insights into the performance capabilities of materials under load.

By understanding the different regions of the curve and the properties of various materials, professionals can make informed decisions that can result in safer, more efficient structures.

By keeping beam stress-strain curves in mind, engineers can innovate while ensuring safety and reliability in design.