In engineering, understanding how beam axial load affects a structural element is essential for ensuring safety and stability.

What is Beam Axial Load?

Beam axial load refers to the longitudinal forces that act along the length of a beam.

These loads can be either tensile or compressive, impacting the beam’s performance and integrity in different ways.

When a beam experiences axial load, it can lead to various outcomes, such as deformation, yielding, or even failure, depending on the magnitude of the load and the material properties of the beam.

How Do Axial Loads Impact Beam Stress?

The stress in a beam due to axial load can be calculated using the formula:

[ \sigma = \frac{P}{A} ]

Where:

– ( \sigma ) = stress in the beam

– ( P ) = axial load applied

– ( A ) = cross-sectional area of the beam

Types of Stress from Axial Load

-

Tensile Stress:

– Occurs when the axial load pulls the beam apart.

– It can lead to elongation of the beam. -

Compressive Stress:

– Happens when the axial load pushes the beam together.

– This may result in shortening and potentially buckling if the load is excessive.

Importance of Stress Analysis

Analyzing stress is crucial for:

- Designing safe structures: Ensures that beams can withstand expected loads.

- Identifying potential failure points: Helps engineers understand where a beam may fail under load.

How Does Axial Load Affect Beam Deflection?

Beam axial load can also contribute to deflection.

Deflection is the degree to which a structural element deforms under loading.

Measuring Deflection

The formula for calculating deflection due to an axial load is:

[ \delta = \frac{PL}{AE} ]

Where:

– ( \delta ) = deflection

– ( P ) = axial load

– ( L ) = length of the beam

– ( A ) = cross-sectional area

– ( E ) = modulus of elasticity of the beam material

Deflection is influenced by several factors:

- Magnitude of the load: Greater loads produce more deflection.

- Length of the beam: Longer beams tend to deflect more.

- Material properties: Different materials have different stiffness, affecting deflection.

What Are the Effects of Axial Load on Different Beam Materials?

Different beam materials react uniquely to axial loads.

Here’s a brief overview:

-

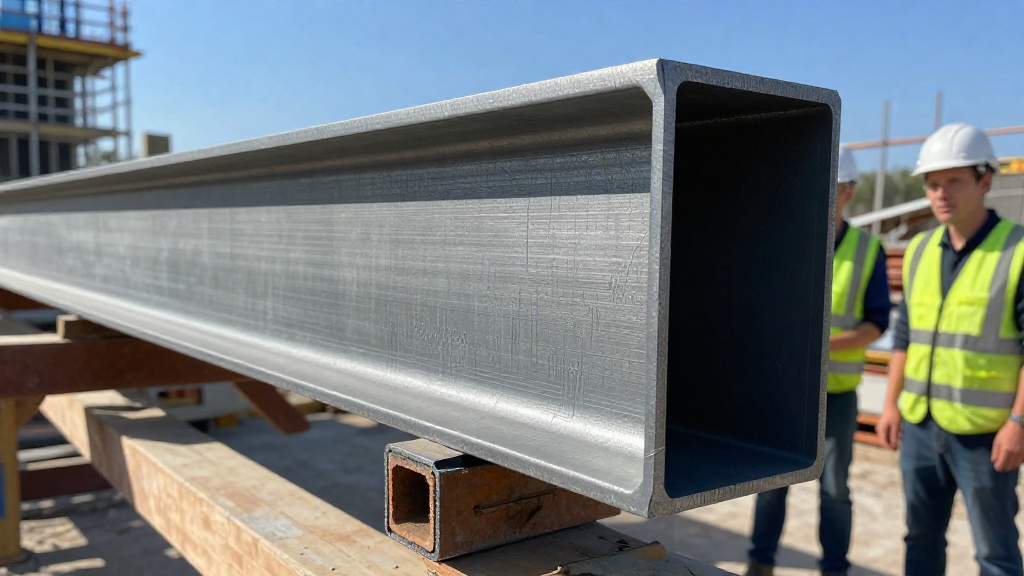

Steel Beams:

– High tensile and compressive strength.

– Can handle significant axial loads before yielding. -

Concrete Beams:

– Strong in compression but weak in tension.

– Often require reinforcement with steel bars. -

Wood Beams:

– Vary widely in strength depending on species.

– Susceptible to buckling under axial load, especially when slender.

Material Considerations for Axial Load

- When selecting materials, think about their modulus of elasticity, yield strength, and compression/tension behavior.

- Different applications may require beams with specific characteristics tailored to the axial load they will be subjected to.

How Can Axial Load Lead to Beam Failure?

Understanding how beam axial load affects structural integrity is essential to prevent failure.

Possible Modes of Failure

-

Buckling:

– A structural instability that occurs when the compressive load exceeds a critical limit.

– Common in slender beams subjected to axial load. -

Yielding:

– Occurs when the beam material reaches its yield strength.

– This may cause permanent deformation and compromise the structure. -

Crushing:

– This can happen when a compressive load exceeds the capacity of the material, especially in concrete.

Signs of Potential Failure

- Excessive deflection or deformation

- Visible cracks in the beam material

- Sounds of creaking or popping under load

How Do Engineers Mitigate the Effects of Axial Load on Beams?

In engineering design, there are several approaches to ensuring beams can withstand axial loads without failure.

Design Strategies

-

Increasing the Cross-Sectional Area:

– A larger area can help distribute the load and reduce stress. -

Selecting High-Strength Materials:

– Choosing materials with higher tensile and compressive strength can prevent failure. -

Implementing Reinforcements:

– For materials like concrete, adding steel reinforcement bars can significantly improve performance under axial loads. -

Shortening Beam Length:

– A shorter span generally leads to less deflection and makes the beam stiffer.

Regular Inspection and Maintenance

- Regular inspections can help identify issues before they lead to failure.

- Maintenance may involve reinforcing existing beams or replacing them if they show signs of distress.

Conclusion: Understanding Beam Axial Load is Essential

The impact of beam axial load on structural performance is a critical aspect of engineering design.

From stress and deflection to material behavior and failure modes, recognizing how axial loads affect beams can significantly influence the safety and integrity of structures.

By using proper design strategies, selecting appropriate materials, and maintaining structures, engineers can ensure that beams perform reliably under various loading conditions.

Always consider the unique requirements of each project and the specific axial load conditions it will face to optimize performance and safety.