When it comes to construction and engineering, beam composite materials have become essential for creating stronger, lighter, and more durable structures.

Understanding the types of materials that can be used in beams is crucial for engineers.

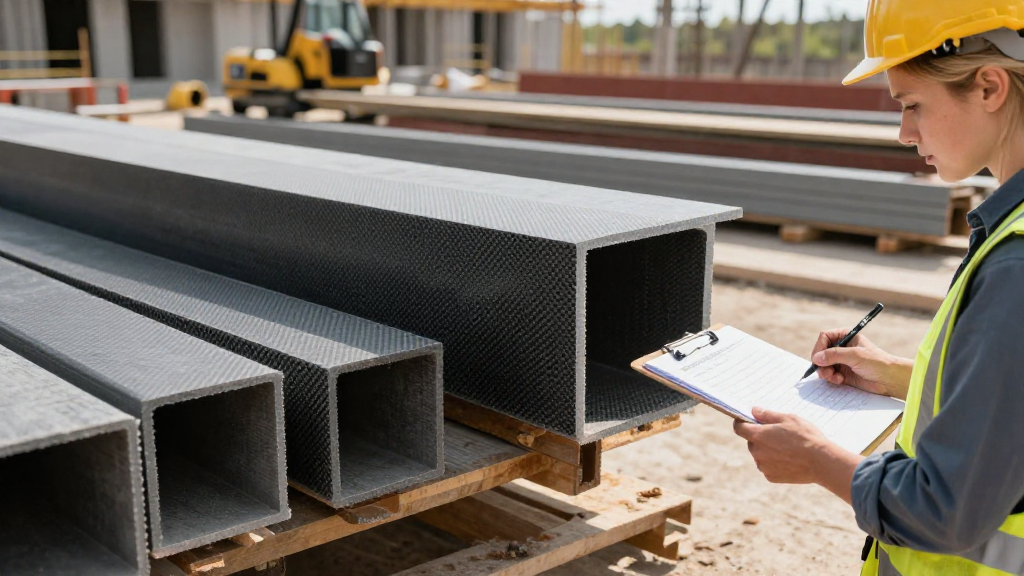

What Are Beam Composite Materials?

Beam composite materials consist of two or more constituent materials that combine to create a material with superior properties compared to individual components.

They are designed to optimize performance in accordance with structural demands.

Key characteristics of beam composite materials include:

- High strength-to-weight ratio

- Enhanced durability

- Resistance to corrosion

- Flexibility in design

These properties make beam composite materials ideal for various applications in construction, aerospace, and automotive sectors.

What Types of Composite Materials Are Used in Beams?

Several types of composite materials are commonly used in beams.

Here’s a breakdown of some of the most prevalent materials:

1. Fiber-Reinforced Polymer (FRP)

FRPs are composed of a polymer matrix reinforced with fibers such as glass, carbon, or aramid.

They excel in applications requiring:

- Lightweight structures

- High tensile strength

- Corrosion resistance

FRP beams are often used in bridge construction and in retrofitting existing structures for enhanced performance.

2. Concrete Reinforced with Steel (Reinforced Concrete)

Reinforced concrete combines concrete with steel reinforcement bars (rebar).

This composite material is popular due to:

- Excellent compressive strength of concrete

- High tensile strength from the steel

Reinforced concrete beams are common in buildings, highways, and various construction projects around the world.

3. Wood Composites

Wood composites, such as laminated veneer lumber (LVL) and cross-laminated timber (CLT), combine layers of wood veneers bonded together to create structural beams.

Key benefits include:

- Sustainable material from renewable sources

- Good insulation properties

- Aesthetic appeal

These beam composite materials are making significant inroads in eco-friendly construction.

4. Metal Matrix Composites (MMC)

Metal matrix composites consist of a metal matrix that is reinforced with ceramic or other fibers.

They combine desirable properties like:

- High thermal conductivity

- Improved wear resistance

- Lightweight designs

MMC beams find applications in automotive components and aerospace structures, where performance and weight are critical considerations.

How Are Beam Composite Materials Manufactured?

The manufacturing process of beam composite materials varies depending on the type.

Here’s a brief overview of some common fabrication methods:

1. Pultrusion

This process involves pulling continuous fibers through a resin bath and then through a heated die to create beams of constant cross-section.

Advantages of pultrusion include:

- Cost-effectiveness for large production runs

- Consistent quality and properties

- Ability to create custom shapes

2. Lay-Up Process

In the lay-up process, layers of fabric are laid onto a mold and saturated with resin.

This method allows for:

- Custom designs and shapes

- High flexibility in material selection

It’s often used in creating complex geometries, making it suitable for unique architectural applications.

3. Extrusion

Extrusion involves forcing material through a die to create shapes.

In the context of composite beams, this method provides:

- High production rates

- Ability to achieve specific cross-sectional profiles

4. 3D Printing

An emerging technology in composite materials is 3D printing.

This method can quickly produce intricate beam designs from composite materials, contributing to:

- Reduced waste

- Customization of shape and function

- Speeding up construction timelines

What Are the Advantages of Using Beam Composite Materials?

Utilizing beam composite materials offers a range of benefits:

-

Weight Reduction: Many composites are lighter than traditional materials, resulting in reduced structural loads and foundation size.

-

Strength and Durability: Composite beams can be engineered to withstand specific loads and environmental conditions.

-

Design Flexibility: Various materials and methods enable custom designs that can adapt to specific project needs.

-

Corrosion Resistance: Certain composites, like FRPs, resist corrosion, making them ideal for structures exposed to harsh environments.

Where Are Beam Composite Materials Commonly Used?

Beam composite materials have versatile applications across various industries, including:

1. Construction

In modern buildings and infrastructure, composites are used in:

- Beams and columns

- Reinforced bridges

- Retrofitting existing structures

2. Aerospace

In the aerospace industry, composites help create lightweight yet strong components, including:

- Wing structures

- Fuselage components

- Engine mounts

3. Automotive

Automobile manufacturers use composites to improve fuel efficiency and performance, particularly in:

- Frame components

- Body panels

- Suspension systems

4. Marine

The marine industry benefits from the corrosion resistance of composites in applications such as:

- Hulls and decks of boats

- Underwater construction structures

- Wind turbines

What Is the Future of Beam Composite Materials?

The future looks promising for beam composite materials.

With advancements in technology and materials science, we expect to see:

-

Increased Use of Smart Materials: Incorporating sensors and other technologies for real-time structural monitoring.

-

Biocomposites: Development of environmentally friendly alternatives that use renewable sources.

-

Cost-Effective Production Techniques: Innovations in manufacturing methods that lower costs and energy consumption.

Conclusion

In summary, beam composite materials are revolutionizing the way we build and design structures.

From lightweight FRPs to reinforced concrete, these materials offer various benefits that improve performance, efficiency, and sustainability.

As technology advances, the potential applications and performance of beam composite materials will only continue to expand, providing innovative solutions for future construction and engineering challenges.

By understanding the types and benefits of these materials, engineers and architects can make informed decisions that enhance both safety and aesthetics in their projects.